About Infrared Thermography About Infrared Thermography

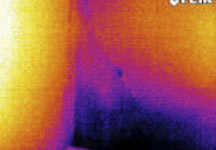

Thermography is the use of an infrared imaging and measurement camera to "see" and "measure" thermal energy emitted from an object. Thermal, or infrared energy, is light that is not visible because its wavelength is too long to be detected by the human eye; it's the part of the electromagnetic spectrum that we perceive as heat. Unlike visible light, in the infrared world, everything with a temperature above absolute zero emits heat. Even very cold objects, like ice cubes, emit infrared. The higher the object's temperature, the greater the IR radiation emitted. Infrared allows us to see what our eyes cannot. Infrared Thermography cameras produce images of invisible infrared or "heat" radiation and provide precise non-contact temperature measurement capabilities. Nearly everything gets hot before it fails, making infrared cameras extremely cost-effective, valuable diagnostic tools in many diverse applications. History of Infrared Technology Sir William Herschel, an astronomer, discovered infrared in 1800. He built his own telescopes and was therefore very familiar with lenses and mirrors. Knowing that sunlight was made up of all the colors of the spectrum, and that it was also a source of heat, Herschel wanted to find out which color(s) were responsible for heating objects. He devised an experiment using a prism, paperboard, and thermometers with blackened bulbs where he measured the temperatures of the different colors. Herschel observed an increase in temperature as he moved the thermometer from violet to red in the rainbow created by sunlight passing through the prism. He found that the hottest temperature was actually beyond red light. The radiation causing this heating was not visible; Herschel termed this invisible radiation "calorific rays." Today, we know it as infrared. How Do Infrared Cameras Work  An infrared camera is a non-contact device that detects infrared energy (heat) and converts it into an electronic signal, which is then processed to produce a thermal image on a video monitor and perform temperature calculations. Heat sensed by an infrared camera can be very precisely quantified, or measured, allowing you to not only monitor thermal performance, but also identify and evaluate the relative severity of heat-related problems. Recent innovations, particularly detector technology, the incorporation of built-in visual imaging, automatic functionality, and infrared software development, deliver more cost-effective thermal analysis solutions than ever before. Digital image storage produces calibrated thermal images that contain over 78,000 independent temperature measurements that can be measured at any time. Infrared Detection for the Building Diagnostics Industry Moisture in building materials can destroy structural integrity and nurture mold. The first step in moisture problem remediation is to quickly and accurately locate and remove all sources of moisture. Infrared Thermography instantly shows you what's wet and what's dry. Using this technology, Murray Construction Services, Inc. in most cases, can instantly find the ultimate source with little or no physical disassembly of the premises and minimal disturbance of inhabitants. Case Studies Investigation of interior plumbing leak The photos below show a rather large water leak. The obvious source of the leak was the main discharge pipe which caused the wall in the basement to be completely soaked. The affected area was rather large; therefore it was very difficult to understand where the pipe was located inside the wall.   Thermal and visual evidence of the leak To create the necessary thermal contrast, hot water from the plumbing was used and the pipe is located using Infrared Thermography.   Once the interior pipe was located, it is a simple calculation to locate the pipe position by measuring the distance from the side of the window at the exterior wall. Unfortunately the pipe was buried where an internal wall existed. Using an old inspection gate to work under the floor without having to remove it or break into an internal wall a crack at the plumbing elbow is discovered.  Investigation of a possible roof leak The following inspection was performed using an infrared camera to produce a heat diagram or a visible image using the infrared spectrum. This imaging technique is a powerful and noninvasive means of monitoring and diagnosing the condition of buildings. A wet spot when observed with an infrared camera is visible as a distinct cool spot. The purpose of this inspection was to investigate water intrusion at the header of the dining area window.   Digital Photo of header over dining area window and IR image of the same. During the Murray Construction Services inspection of the header over

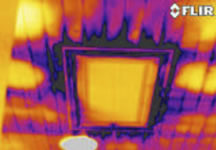

a single pane clear aluminum window, we found evidence of light water

stains at the header window wrap. It appears that moisture has penetrated

the building envelope and found its way in between the drywall and the

window frame at the header. Light moisture was present as shown in the

above IR image. Murray Construction Services confirmed our findings using

a non penetrating moisture detector. Deterioration of the drywall was

also noted where the window wrap meets the sill at both sides of the

window. This is a common result of condensation build up with single

pane windows. |

|

Sample Images

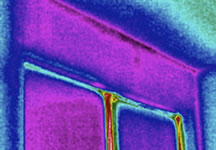

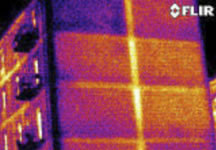

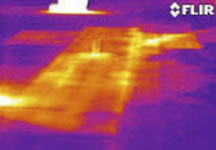

In these images, an infrared survey was conducted during daytime hours to reveal a central area of a ceiling that is saturated with moisture and in need of immediate repair.

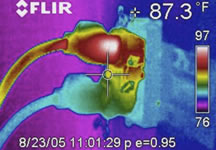

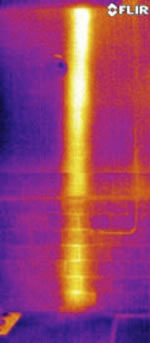

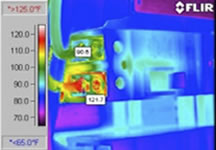

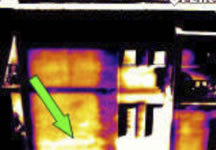

In these images, an infrared survey was conducted because of a continued electrical issue which caused the breakers to trip. The 110 Amp circuit breaker, B phase exceeds 80 percent ampacity and the temperature exceeds the breaker rating, causing the breaker to trip.

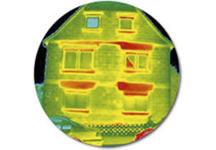

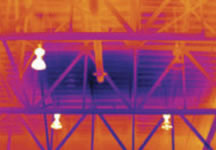

There are many other possible uses of this technology for buildings. Sometimes they are just limited to the time needed to find the right moment to perform the inspection, for instance, by waiting for solar radiation to create the thermal contrast needed, or arranging the heating by using a big hot air gun or a set of lamps. Infrared Thermography's use for building applications is incredibly large because it is a noninvasive test and fast to perform. Below are a few of the applications where infrared Thermography has proven useful.

Heat loss indicating Insufficient insulation.

Location of hidden structures within walls that is not obvious to the naked eye.

Disbonding tiles.

Subsurface roof moisture.

Air leakage in window due to insufficient insulation.

Peeling Plaster.

Peeling Plaster.

Moisture in walls from cracks in stucco.

Moisture in walls from cracks in stucco. |

|

||